¨ç Impact resistance : Protecting life and property from all kinds of safety or robbery accident owing to strength by 250 times of plate glass, 150 times of reinforced glass and 30 times of acryl

¨è Excellent insulation and electrical insulation : Reducing cooling and heating expenses due to higher thermal efficiency by lower heat transfer coefficient than plate glass

¨é Constructability : Available in various forms and purposes owing to flexibility, saving installation expenses due to light weight because the specific gravity is a half of glass, and easy handling

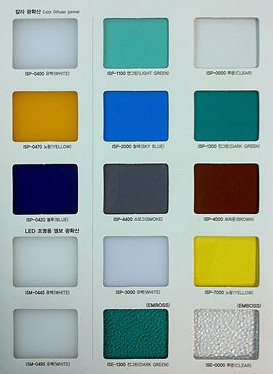

¨ê Visibility : Clear and beautiful surface gloss like plate glass due to 85% or more of transmission of a visible ray, and more diversified colors than plastic products

¨ë Insulation and UV block : Saving energy by virtue of excellent insulation and UV block and preventing furniture and art works from discoloration by sunlight

¨ì Durability : Keeping high physical properties owing to excellent weather resistance as well as performance against severe temperature changes due to excellent thermal and cold resistance, self-extinguishing, and never generating toxic gases

¨í Excellent electrical properties and satisfactory dimensional stability